What is the difference between 6000w fiber laser cutting machine and 3000w fiber laser cutting machine?

Table of Contents

Since the official emergence of fiber laser cutting machine in 2011, in the following years, optical fiber laser cutting machine has gradually occupied the entire cutting market with a high-speed development trend, and has replaced the traditional CO2 laser cutting technology. As of this year, fiber laser cutting machine has been continuously upgraded in terms of power, and 6kw fiber laser cutting machine is becoming more and more popular, which can meet the processing of most metal materials.

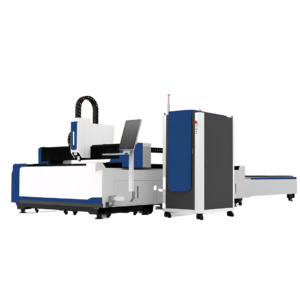

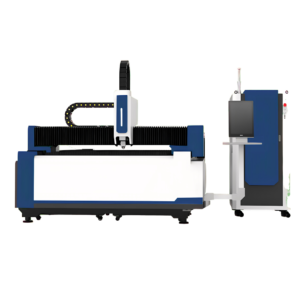

In recent years, Alpha Laser has also been continuously upgrading fiber laser cutting machine, on the basis of 3000w metal furniture laser cutting machine. 6kw fiber laser cutting machine and higher power metal fiber laser cutting machine also came into being, but many people may not understand the difference between 6kw fiber laser cutting machine and 3000w, today we will conduct a comprehensive comparative analysis of 6000W and 3000w fiber laser cutting machine.

1. Carbon steel bright cut for 6000w fiber laser cutting machine and 3000w metal furniture laser cutting machine

From the analysis of the cutting thickness of metal fiber laser cutting machine, the bright cutting thickness of 3000 watt fiber laser cutting machine is about 10MM; compared with 3000 watt fiber laser cutting machine, the bright cutting thickness of 6000w fiber laser cutter is much larger than that of 3000w metal furniture laser cutting machine, and the bright cutting thickness of 16MM or less can be cut, and Fast cutting speed and good verticality.

2. Full power cutting of carbon steel with 3000w fiber laser cutting machine and 6kw fiber laser cutting machine

Full power cutting is 100% power cutting. 6kw fiber laser cutting machine has the advantages of high electro-optical conversion efficiency, good beam quality and high power density. Small and other advantages, so carbon steel materials with a thickness of 16-25mm can be cut with 6kw fiber laser cutting machine.

3. Stainless steel cutting with 3000 watt fiber laser cutter and 6000w fiber laser cutter

Compared with 3000 watt fiber laser cutter, the 6000WAAA complete machine complies with the safety standards of laser equipment in developed countries in Europe and the United States. Using laser beam cutting, compared with 3000 watt fiber laser cutter , the cutting speed of 6000w fiber laser cutter can be increased by 140%~330%, which can effectively improve work efficiency.

4. 3000w metal furniture laser cutting machine and 6000w fiber laser cutting machine burr-free cutting

Commonly used metal fiber laser cutting machine uses oxygen or nitrogen for operation. When the section requirements are not high, metal fiber laser cutting machine can also use air for cutting on this basis. The air is compressed into the storage tank by the air compressor and cooled by the filter cooler. It can be used after drying, so it can effectively reduce the user’s use cost.

In the same brand of metal fiber laser cutting machine, 3000w fiber laser cutter can cut 2.5mm thick carbon steel and 10mm stainless steel materials without burrs; on the other hand, 6000w fiber laser cutting machine can cut 5mm thick carbon steel and 16mm stainless steel materials without burrs, in the same brand and the same type of optical fiber Among laser cutting machines, 6000 watt fiber laser cutter can process material thickness far exceeding that of 3000w fiber laser cutter.

With the continuous development and upgrading of Alpha Laser metal fiber laser cutting machine, the cutting power of Alpha Laser metal fiber laser cutting machine has far exceeded 6000W. The cutting power of large-format gantry-type planar metal fiber laser cutting machine equipped with fiber laser can reach 50000W, and the processing range can be extended infinitely. The guide rail extends infinitely, and multiple sheets are cut synchronously, which is suitable for large-scale, medium-thick plate batch processing.